| е“ҒзүҢпјҷь/td> | еёёе·һдҪіеҸ‘ |

| дә§ең°пјҷь/td> | еёёе·һ |

| е…іжіЁеәҰпјҡ | 6483 |

| еһӢеҸ·пјҷь/td> | PLG |

е№ІзҮҘд»ӢиҙЁпјҷьspan>е…¶е®ғ

йҖӮз”Ёзү©ж–ҷпјҷьspan>еӨҡз§ҚеҸҜз”Ё

ж“ҚдҪңж–№ејҸпјҷьspan>иҝһз»ӯејҺь/span>

е·ҘдҪңеҺҹзҗҶпјҷьspan>е…¶д»–

жҰӮиҝ°пјҷь/span>

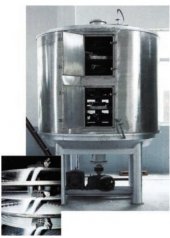

вҳ…зӣҳејҸиҝһз»ӯе№ІзҮҘеҷЁжҳҜдёҖз§Қй«ҳ

ж•Ҳзҡ„дј еҜјеһӢиҝһз»ӯе№ІзҮҘи®ҫеӨҮгҖӮе…¶зӢ¬зү№зҡ„з»“жһ„е’Ңе·ҘдҪңеҺҹзҗҶеҶіе®ҡдәҶе®ғе…·жңүзғӯж•ҲзҺҮй«ҳгҖҒиғҪиҖ—дҪҺгҖҒеҚ ең°йқўз§Ҝе°ҸгҖҒй…ҚзҪ®з®ҖеҚ•гҖҒж“ҚдҪңжҺ§еҲ¶ж–№дҫҝгҖҒж“ҚдҪңзҺҜеўғеҘҪзӯүзү№зӮ№пјҢе№ҝжіӣйҖӮз”ЁдәҺеҢ–е·ҘгҖҒеҢ»иҚҜгҖҒеҶңиҚҜгҖҒйЈҹе“ҒгҖҒйҘІж–ҷгҖҒеҶңеүҜдә§е“ҒеҠ е·ҘзӯүиЎҢдёҡзҡ„е№ІзҮҘдҪңдёҡгҖӮеңЁеҗ„иЎҢдёҡдҪҝз”Ёе®һи·өдёӯж·ұеҸ—еҘҪиҜ„гҖӮе…Ҳз”ҹдә§еҲ¶йҖ еёёеҺӢгҖҒеҜҶй—ӯгҖҒзңҹз©әдёүеӨ§зұ»еһӢпјҢ1200гҖ?500гҖ?200гҖ?000еӣӣз§Қи§„ж јпјҢA(зўій’ў)гҖҒB

пјҲжҺҘи§Ұзү©дәҶйғЁеҲҶеқҮеҢҖдёҚй”Ҳй’ўпјүгҖ?/span>CпјҲеңЁBзҡ„еҹәзЎҖдёҠпјҢеўһеҠ и’ёжұҪз®Ўи·ҜпјҢдё»иҪҙеҸҠж”Ҝжһ¶дёәдёҚй”Ҳй’ўпјҢзӯ’дҪ“е’ҢйЎ¶зӣ–еҶ…иЎ¬дёҚй”Ҳй’ўпјүгҖӮдёүз§ҚжқҗиҙЁпјҢе№ІзҮҘйқўз§Ҝ4-180 пјҢе…ұеҮ зҷҫз§ҚеһӢеҸ·зҡ„зі»еҲ—дә§е“ҒпјҢ并жҸҗдҫӣдёҺд№Ӣзӣёй…ҚеҘ—зҡ„иҫ…еҠ©и®ҫеӨҮпјҢеҸҜж»Ўи¶із”ЁжҲ·еҜ№еҗ„з§Қзү©ж–ҷиҝӣиЎҢе№ІзҮҘзҡ„йңҖжұӮгҖҒь/span>

еҺҹзҗҶпјҷь/span>

вҳ…ж№ҝзү©ж–ҷиҮӘеҠ ж–ҷеҷЁиҝһз»ӯең°еҠ еҲ°е№ІзҮҘеҷЁдёҠйғЁ**еұӮе№ІзҮҘзӣҳдёҠпјҢеёҰжңүиҖҷеҸ¶зҡ„иҖҷиҮӮеҒҡеӣһиҪ¬иҝҗеҠЁдҪҝиҖҷеҸ¶иҝһз»ӯең°зҝ»жҠ„зү©ж–ҷгҖӮзү©ж–ҷжІҝжҢҮж•°иһәж—ӢзәҝжөҒиҝҮе№ІзҮҘзӣҳиЎЁйқўпјҢеңЁе°Ҹе№ІзҮҘзӣҳдёҠзҡ„зү©ж–ҷ被移йҖҒеҲ°еӨ–зјҳпјҢ并еңЁеӨ–зјҳиҗҪеҲ°дёӢж–№зҡ„еӨ§е№ІзҮҘзӣҳеӨ–зјҳпјҢеңЁеӨ§е№ІзҮҘзӣҳдёҠзү©ж–ҷеҗ‘йҮҢ移еҠЁе№¶д»Һдёӯй—ҙиҗҪж–ҷеҸЈиҗҪе…ҘдёӢдёҖеұӮе°Ҹе№ІзҮҘзӣҳдёӯгҖӮеӨ§е°Ҹе№ІзҮҘзӣҳдёҠдёӢдәӨжӣҝжҺ’еҲ—пјҢзү©ж–ҷеҫ—д»Ҙиҝһз»ӯең°жөҒиҝҮж•ҙдёӘе№ІзҮҘеҷЁгҖӮдёӯй—ҙзҡ„е№ІзҮҘзӣҳеҶ…йҖҡе…ҘеҠ зғӯд»ӢиҙЁпјҢеҠ зғӯд»ӢиҙЁеҪўејҸжңүйҘұе’Ңи’ёжұҪгҖҒзғӯж°ҙе’ҢеҜјзғӯжІ№пјҢеҠ зғӯд»ӢиҙЁз”ұе№ІзҮҘзӣҳзҡ„дёҖз«Ҝиҝӣе…ҘпјҢд»ҺеҸҰдёҖз«ҜеҜјеҮәгҖӮе·Іе№Ізү©ж–ҷд»Һ*еҗҺдёҖеұӮе№ІзҮҘзӣҳиҗҪеҲ°еЈідҪ“зҡ„еә•еұӮпјҢ*еҗҺиў«иҖҷеҸ¶з§»йҖҒеҲ°еҮәж–ҷеҸЈжҺ’еҮәгҖӮж№ҝд»Ҫд»Һзү©ж–ҷдёӯжәўеҮәпјҢз”ұи®ҫеңЁйЎ¶зӣ–дёҠзҡ„жҺ’ж№ҝеҸЈжҺ’еҮәпјҢзңҹз©әеһӢзӣҳејҸе№ІзҮҘеҷЁзҡ„ж№ҝж°”з”ұи®ҫеңЁйЎ¶зӣ–дёҠзҡ„зңҹз©әжіөеҸЈжҠҪеҮәгҖӮд»Һеә•еұӮжҺ’еҮәзҡ„е№Ізү©ж–ҷеҸҜзӣҙжҺҘеҢ…иЈ…гҖӮйҖҡиҝҮй…ҚеӨҮзҝ…зүҮеҠ зғӯеҷЁгҖҒжә¶еүӮеӣһ收еҶ·еҮқеҷЁгҖҒеёғиўӢйҷӨе°ҳеҷЁгҖҒе№Іж–ҷиҝ”ж··жңәжһ„гҖҒеј•йЈҺжңәзӯүиҫ…жңәпјҢеҸҜжҸҗй«ҳе…¶е№ІзҮҘзҡ„з”ҹдә§иғҪеҠӣпјҢ е№ІзҮҘиҶҸзіҠзҠ¶е’Ңзғӯж•ҸжҖ§зү©ж–ҷпјҢеҸҜж–№дҫҝең°еӣһ收жә¶еүӮпјҢ并иғҪиҝӣиЎҢзғӯи§Је’ҢеҸҚеә”ж“ҚдҪңгҖҒь/span>

вҳ„ь/span>Wet materials are fed continuously to the top drying layer in the drier. They will be turned and stirred continuously by harrowsвҖ s arm rotates, the material flows through the surface will be moved to its exterior edge and drop down ti the exterior edge of the large drying plate underneath, And will then be moved inward and drop down form its central hole to the small drying plate on the next layer. Both small and large drying plates are arranged alternately so as materials can go through the whole drier continuously. The heating media, which could be saturated steam, hot water or thermal oil will be led into drying plates from one end to other end of the drier. The dried product will drop from the last layer of the drying plate to the bottom layer of the body, and will be moved by harrows to the discharge outlet. The moisture exhausts from materials and will be removed from the moist discharge outlet on the top cover, or sucked out by the vacuum pump on the top cover for vacuum-type plate drier. The dried product discharged form the bottom layer can be cover for vacuum-type plate drier. The dried product discharged from the bottom layer can be packed directly. The drying capability can be raised up if equipped with supplementary devices such as finned heater, condenser for solvent recovery, bag dust filter, return and mix mechanism for dried materials and suction fan etc. solvent in those paste state and heat sensitive materials can be easily recovered, and thermal decomposition and reaction can be also carried out.

жҠҖжңҜеҸӮж•°пјҡ

йҮ‘зүҢдјҡе‘ҳ

йҮ‘зүҢдјҡе‘ҳ е·Іи®ӨиҜ?/p>

е·Іи®ӨиҜ?/p>