зҷ»еҪ•

- APP

- зІүдә«йҖҷь/a>

- 188188188b.comҪрұҰІ©

еҫ®дҝЎ

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

- дёӯеӣҪзІүдҪ“зҪҗь/a>

移еҠЁз«?/p>

移еҠЁз«?/p>

m.cnpowder.com.cn

m.cnpowder.com.cn

зҷ»еҪ•

еҫ®дҝЎ

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

![]() 移еҠЁз«?/p>

移еҠЁз«?/p>

m.cnpowder.com.cn

m.cnpowder.com.cn

еҸӮиҖғд»·ж »ь/p>йқўи®®

еһӢеҸ·

TLе“ҒзүҢ

зҡ–ж°ҹйҫҳь/span>дә§ең°

дёӯеӣҪж ·жң¬

жҡӮж—

дјҡе‘ҳ

|з¬?е№іь/p>|

з”ҹдә§е•…ь/p>

![]() е·Ҙе•Ҷе·Іж ёе®қь/p>

е·Ҙе•Ҷе·Іж ёе®қь/p>

з•ҷиЁҖиҜўд»·

з•ҷиЁҖиҜўд»·

зңӢдәҶз«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„з”ЁжҲ·еҸҲзңӢдә…ь/p>

з•ҷиЁҖиҜўд»·

з•ҷиЁҖиҜўд»·

иҷҡжӢҹеҸ·е°Ҷең180з§’еҗҺеӨұж•Ҳ

дҪҝз”Ёеҫ®дҝЎжү«з ҒжӢЁеҸ·

| еҗҚз§°пјҷь/span> | TLз«ӢејҸз®ЎйҒ“зҰ»еҝғжі?IHGз«ӢејҸзҰ»еҝғжі? IHGж°ҙжіө/ ISGзҰ»еҝғжі?зҰ»еҝғжі?з®ЎйҒ“зҰ»еҝғжіҙь/td> |

| иҫ“йҖҒд»ӢиҙЁпјҡ | иҫ“йҖҒдҪҺжё©еәҰжҲ–й«ҳжё©ж¶ІдҪ“гҖҒдёӯжҖ§жҲ–жңүи…җиҡҖжҖ§ж¶ІдҪ’ь/td> |

| йҖӮз”ЁиЎҢдёҡпјҷь/span> | зҹіжІ№пјҢеҢ–е·ҘпјҢеҶ¶зӮјпјҢз…ӨеҢ–е·ҘпјҢеәҹж°ҙпјҢзҺҜдҝқпјҢжө·еҢ–ж·ЎеҢ•ь/td> |

| дә§е“Ғзү№зӮ№пјҷь/span> | еә•и„ҡж”Ҝж’‘пјҢеўһеҺҠь/td> |

| з»“жһ„еҪўејҸпјҷь/span> | еӣҪж ҮгҖҒз«ӢејҸгҖҒжіөдёҺз”өжңәзӣҙиҝқь/td> |

| еҸЈеҫ„пјҷь/span> | 25пҪ?00mm |

| жөҒйҮҸпјҷь/span> | пҪ?00 m3/h |

| жү¬зЁӢпјҷь/span> | пҪ?25m |

| иҪ¬йҖҹпјҡ | 1450/2900r/min |

| е·ҘдҪңжё©еәҰпјҷь/span> | -20пҪ?120в„Ӯь/td> |

| еҺӢеҠӣзӯүзә§пјҷь/span> | 1.6Mpa |

| еҠҹзҺҮпјҷь/span> | пҪ?32KW |

| жқҗж–ҷпјҷь/span> | 304гҖ?04LгҖ?16гҖ?16LгҖ?205гҖҒHC276гҖҒTA2 |

дёҖгҖҒдә§е“Ғз®Җд»Ӣпјҡ

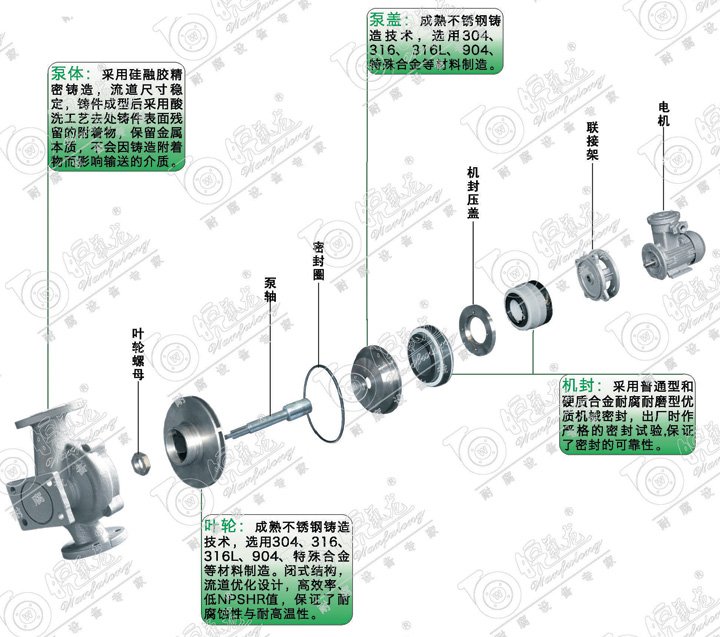

дә§е“ҒжҰӮиҝ°пјҷьbr/>TLдә§е“Ғжү§иЎҢGB5656-1994гҖҠзҰ»еҝғжіөжҠҖжңҜжқЎд»?II)зұ»гҖӢж ҮеҮҶгҖӮйҮҮз”ЁCFDи®Ўз®—жөҒдҪ“еҠЁеҠӣеӯҰпјҢеҲҶжһҗи®Ўз®—еҮәжіөеҶ…еҺӢеҠӣеҲҶеёғе’ҢйҖҹеәҰеҲҶеёғе…ізі»гҖҒдјҳеҢ–жіөзҡ„жөҒйҒ“и®ҫи®ЎпјҢзЎ®дҝқжіөжңүй«ҳж•Ҳзҡ„ж°ҙеҠӣеҪўзә?жҸҗй«ҳдәҶжіөзҡ„ж•ҲзҺҮпјҢйҮҮз”Ёе…Ҳиҝӣзҡ„еҸҢиҠӮжөҒзҺҜе№іиЎЎжі•пјҢиҪҙеҗ‘еҠӣе№іиЎЎж•ҲжһңеҘҪпјҢжңүж•ҲеҮҸе°‘з”өжңәж•…йҡңзҺҮпјҢжҸҗй«ҳиҝҗиЎҢеҸҜйқ жҖ§пјӣе№іиЎЎзІҫеәҰй«ҳпјҢе№ҝжіӣйҖӮз”ЁдәҺзҹіжІ№гҖҒеҢ–е·ҘгҖҒзәәз»ҮеҚ°жҹ“гҖҒеҲ¶иҚҜгҖҒйЈҹе“ҒгҖҒеҶ¶йҮ‘гҖҒз”өз«ҷзӯүиҫ“йҖҒи…җиҡҖжҖ§д»ӢиҙЁеҸҠжңүзү№ж®ҠиҰҒжұӮзҡ„д»ӢиҙЁгҖҒьbr/>дә§е“ҒдјҳзӮ№пјҷьbr/>1.TLдёҚй”Ҳй’ўз«ӢејҸз®ЎйҒ“зҰ»еҝғжіөжҳҜжҢүGB5656-1994зҡ„е·Ҙиүәи®ҫи®ЎеҲ¶йҖ пјҢйҮҮз”ЁCFDи®Ўз®—жөҒдҪ“еҠЁеҠӣеӯҰпјҢеҲҶжһҗи®Ўз®—еҮәжіөеҶ…еҺӢеҠӣеҲҶеёғе’ҢйҖҹеәҰеҲҶеёғе…ізі»гҖҒдјҳеҢ–жіөзҡ„жөҒйҒ“и®ҫи®ЎпјҢзЎ®дҝқжіөжңүй«ҳж•Ҳзҡ„ж°ҙеҠӣеҪўзә?жҸҗй«ҳдәҶжіөзҡ„ж•ҲзҺҮгҖҒьbr/>2. жіөзҡ„иҝҮжөҒйғЁд»¶еҰӮжіөдҪ“гҖҒеҸ¶иҪ®гҖҒжіөзӣ–гҖҒеҜҶе°ҒзҺҜзӯүпјҢйҮҮз”ЁзЎ…иһҚиғ¶зІҫеҜҶй“ёйҖ пјҢжөҒйҒ“е°әеҜёзЁіе®ҡпјҢ铸件жҲҗеһӢеҗҺйҮҮз”Ёй…ёжҙ—е·ҘиүәеҺ»еӨ„铸件表йқўж®Ӣз•ҷзҡ„йҷ„зқҖзү©пјҢдҝқз•ҷйҮ‘еұһжң¬иҙЁпјҢдёҚдјҡеӣ й“ёйҖ йҷ„зқҖзү©иҖҢеҪұе“Қиҫ“йҖҒзҡ„д»ӢиҙЁгҖҒьbr/>3.йҮҮз”Ёжҷ®йҖҡеһӢе’ҢзЎ¬иҙЁеҗҲйҮ‘иҖҗи…җиҖҗзЈЁеһӢдјҳиҙЁжңәжў°еҜҶе°ҒпјҢеҮәеҺӮж—¶дҪңдёҘж јзҡ„еҜҶе°ҒиҜ•йӘ?дҝқиҜҒдәҶеҜҶе°Ғзҡ„еҸҜйқ жҖ§гҖҒьbr/>4.иҪҙиҒ”еҗҺжӢүејҸи®ҫи®ЎпјҢиҝӣеҮәеҸЈеҸЈеҫ„зӣёеҗҢдё”еңЁдёҖжқЎзӣҙзәҝдёҠпјҢж— йңҖжӢҶеҚёз®ЎйҒ“пјҢз»ҙдҝ®ж–№дҫҝпјӣ

5.ж— йңҖзӢ¬з«Ӣж¶Ұж»‘е’ҢеҶ·еҚҙж°ҙпјҢйҷҚдҪҺдәҶиғҪиҖ—гҖҒьbr/>6.з«ӢејҸе®үиЈ…пјҢз»“жһ„зҙ§еҮ‘гҖҒеҚ ең°йқўз§Ҝе°ҸпјҢжҢҜеҠЁе°ҸпјҢеҷӘйҹідҪҺпјҢиҝҗиЎҢе№ізЁІьbr/>7.йҮҮз”Ёе…Ҳиҝӣзҡ„еҸҢиҠӮжөҒзҺҜе№іиЎЎжі•пјҢиҪҙеҗ‘еҠӣе№іиЎЎж•ҲжһңеҘҪпјҢжңүж•ҲеҮҸе°‘з”өжңәж•…йҡңзҺҮпјҢжҸҗй«ҳиҝҗиЎҢеҸҜйқ жҖ§пјӣе№іиЎЎзІҫеәҰй«ҳпјҢеҸ¶иҪ®йғЁд»¶еҠЁе№іиЎЎзІҫеәҰдёәG1.0зә§гҖҒьbr/>дә§е“Ғз”ЁйҖ”пјҡ

е№ҝжіӣеә”з”ЁдәҺзҹіжІ№гҖҒеҢ–е·ҘгҖҒеҲ¶зўұгҖҒеҶ¶зӮјгҖҒзЁҖеңҹгҖҒеҶңиҚҜгҖҒжҹ“ж–ҷгҖҒеҢ»иҚҜгҖҒйҖ зәёгҖҒз”өй•ҖгҖҒз”өи§ЈгҖҒж— зәҝз”өгҖҒеҢ–жҲҗз®”гҖҒз§‘з ”жңәжһ„гҖҒеӣҪйҳІе·Ҙдёҡзӯүз”ҹдә§жөҒзЁӢдёӯиҫ“йҖҒи…җиҡҖжҖ§ж¶ІдҪ“пјҢе°Өе…¶йҖӮз”ЁдәҺй«ҳжё©гҖҒејәзўұгҖҒжңүжңәе®№еүӮе’ҢиҙөйҮҚж¶ІдҪ“зҡ„иҫ“йҖҒгҖҒьbr/>жҖ§иғҪиҢғеӣҙпјҷь/strong>и®ҫи®ЎеҺӢеҠӣпј?.6MpaгҖҒжөҒйҮҺъ2-200m3/hгҖҒжү¬зЁӢпјҡ20-125mгҖҒеҠҹзҺҮпјҡ0.55-90kw

йҖӮз”Ёжё©еәҰпјҷь/strong>-20пҪ?20в„ғпјҢйҮҮз”Ёж–°еһӢжқҗж–ҷиҖҗжё©еҸҜиҫҫ180в„ғпјӣ

жіЁж„ҸдәӢйЎ№пјҷь/strong>еҪ“д»ӢиҙЁжҜ”йҮҚеӨ§дә?.3mg/cm3ж—¶и®ўиҙ§ж—¶еә”иҜҙжҳҺпјҢзҰҒжӯўз©әиҝҗиҪ¬пјҢзҰҒжӯўиҫ“йҖҒеҗ«жңүйў—зІ’жҲ–жңүз»“жҷ¶зҡ„д»ӢиҙЁгҖҒь/p>

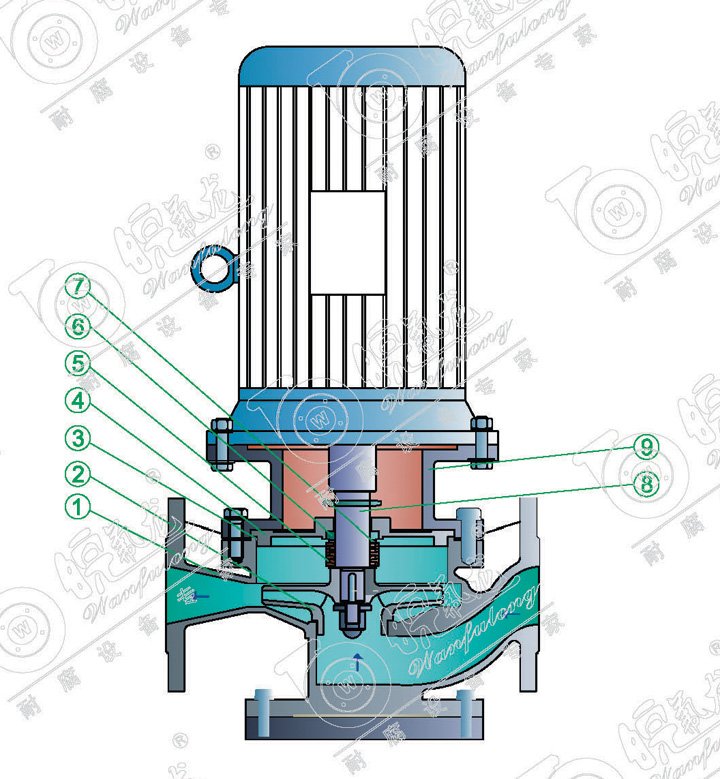

дәҢгҖҒи§Јеү–еӣҫпјҷь/p>

дёүгҖҒз»“жһ„еӣҫпјҷь/p>

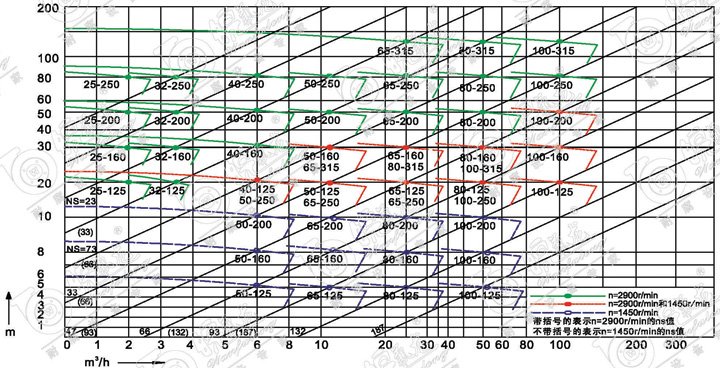

еӣӣгҖҒжҖ§иғҪжӣІзәҝеӣҫпјҡ

дә”гҖҒжҖ§иғҪеҸӮж•°иЎЁпјҡ

| еһӢеҸ· | иҪ¬йҖһьbr/> r/min |

жөҒйҮҸ |

жү¬зЁӢ |

ж•ҲзҺҮ |

жұҪиҡҖдҪҷйҮҸ |

иҝӣеҸЈXеҮәеҸЈ |

з”өжңәеҠҹзҺҮ |

ж•ҙжңәиҙЁйҮҸ |

| TL25-125 | 2900 | 1.5 | 22 | 28 | 2.5 | 25Г—25 | 1.1 | 28 |

| 2 | 20 | 36 | 2.5 | |||||

| 3.2 | 18.5 | 34 | 3 | |||||

| 1450 | 0.75 | 5.4 | 18 | 2.5 | 0.55 | 20 | ||

| 1 | 5 | 22 | 2.5 | |||||

| 1.6 | 4.6 | 28 | 3 | |||||

| TL25-160 | 2900 | 1.5 | 34.3 | 24 | 2.5 | 25Г—25 | 1.5 | 39 |

| 2 | 32 | 32 | 2.5 | |||||

| 3.2 | 29.6 | 33 | 3 | |||||

| 1450 | 0.75 | 8.5 | 17 | 2.5 | 0.55 | 30 | ||

| 1 | 8 | 20 | 2.5 | |||||

| 1.6 | 7.5 | 26 | 3 | |||||

| TL25-200 | 2900 | 1.5 | 52.5 | 28 | 2.5 | 25Г—25 | 7.5 | 41 |

| 2 | 50 | 32 | 2.5 | |||||

| 3.2 | 48 | 30 | 3 | |||||

| 1450 | 0.75 | 13.1 | 15 | 2.5 | 2.2 | 21 | ||

| 1 | 12.5 | 18 | 2.5 | |||||

| 1.6 | 12 | 24 | 3 | |||||

| TL25-250 | 2900 | 1.5 | 82 | 26 | 2.5 | 25Г—25 | 11 | 53 |

| 2 | 80 | 30 | 2.5 | |||||

| 3.2 | 78.5 | 28 | 3 | |||||

| 1450 | 0.75 | 20.5 | 15 | 2.5 | 3 | 43 | ||

| 1 | 20 | 18 | 2.5 | |||||

| 1.6 | 19.5 | 24 | 3 | |||||

| TL32-125 | 2900 | 2 | 22 | 40 | 2.5 | 32Г—32 | 2.2 | 28 |

| 3.2 | 20 | 44 | 2.5 | |||||

| 5.5 | 18.5 | 42 | 3 | |||||

| 1450 | 1 | 5.4 | 32 | 2.5 | 0.55 | 20 | ||

| 1.6 | 5 | 36 | 2.5 | |||||

| 2.75 | 4.6 | 34 | 3 | |||||

| TL32-160 | 2900 | 2 | 34.3 | 34 | 2.5 | 32Г—32 | 3 | 26 |

| 3.2 | 32 | 40 | 2.5 | |||||

| 5.5 | 29.6 | 42 | 3 | |||||

| 1450 | 1 | 8.5 | 24 | 2.5 | 0.55 | 22 | ||

| 1.6 | 8 | 32 | 2.5 | |||||

| 2.75 | 7.5 | 30 | 3 | |||||

| TL32-200 | 2900 | 2 | 52.5 | 32 | 2.5 | 32Г—32 | 7.5 | 30 |

| 3.2 | 50 | 36 | 2.5 | |||||

| 5.5 | 48 | 34 | 3 | |||||

| 1450 | 1 | 13.1 | 25 | 2.5 | 0.55 | 25 | ||

| 1.6 | 12.5 | 28 | 2.5 | |||||

| 2.75 | 12 | 26 | 3 | |||||

| TL32-250 | 2900 | 2 | 82 | 26 | 2.5 | 32Г—32 | 18.5 | 65 |

| 3.2 | 80 | 30 | 2.5 | |||||

| 5.5 | 78.5 | 28 | 3 | |||||

| 1450 | 1 | 20.5 | 15 | 2.5 | 0.75 | 30 | ||

| 1.6 | 20 | 18 | 2.5 | |||||

| 2.75 | 19.5 | 24 | 3 | |||||

| TL40-125 | 2900 | 4.4 | 22 | 41 | 2.5 | 40Г—40 | 1.5 | 34 |

| 6.3 | 20 | 46 | 2.5 | |||||

| 8.3 | 18.5 | 43 | 3 | |||||

| 1450 | 2.2 | 5.4 | 36 | 2.5 | 0.55 | 19 | ||

| 3.2 | 5 | 40 | 2.5 | |||||

| 4.2 | 4.6 | 38 | 3 | |||||

| TL40-160 | 2900 | 4.4 | 34.3 | 35 | 2.5 | 40Г—40 | 3 | 40 |

| 6.3 | 32 | 40 | 2.5 | |||||

| 8.3 | 29.6 | 38 | 3 | |||||

| 1450 | 2.2 | 8.5 | 31 | 2.5 | 0.37 | 38 | ||

| 3.2 | 8 | 35 | 2.5 | |||||

| 4.2 | 7.5 | 33 | 3 | |||||

| TL40-200 | 2900 | 4.4 | 52.5 | 26 | 2.5 | 40Г—40 | 5.5 | 74 |

| 6.3 | 50 | 33 | 2.5 | |||||

| 8.3 | 48 | 32 | 3 | |||||

| 1450 | 2.2 | 13.1 | 25 | 2.5 | 0.55 | 52 | ||

| 3.2 | 12.5 | 28 | 2.5 | |||||

| 4.2 | 12 | 26 | 3 | |||||

| TL40-250 | 2900 | 4.4 | 82 | 24 | 2.5 | 40Г—40 | 11 | 105 |

| 6.3 | 80 | 28 | 2.5 | |||||

| 8.3 | 78.5 | 28 | 3 | |||||

| 1450 | 2.2 | 20.5 | 20 | 2.5 | 1.1 | 52 | ||

| 3.2 | 20 | 24 | 2.5 | |||||

| 4.2 | 19.5 | 22 | 3 | |||||

| TL50-125 | 2900 | 7.5 | 22 | 43 | 2 | 50Г—50 | 2.2 | 33 |

| 12.5 | 20 | 51 | 2 | |||||

| 15 | 18.5 | 49 | 2.5 | |||||

| 1450 | 3.75 | 5.4 | 36 | 2 | 0.55 | |||

| 6.3 | 5 | 45 | 2 | |||||

| 7.5 | 4.6 | 44 | 2.5 | |||||

| TL50-160 | 2900 | 7.5 | 34.3 | 33 | 2 | 50Г—50 | 4 | 40 |

| 12.5 | 32 | 46 | 2 | |||||

| 15 | 29.6 | 50 | 2.5 | |||||

| 1450 | 3.72 | 8.5 | 29 | 2 | 0.55 | |||

| 6.3 | 8 | 40 | 2 | |||||

| 7.5 | 7.5 | 43 | 2.5 | |||||

| TL50-200 | 2900 | 7.5 | 52.5 | 28 | 2 | 50Г—50 | 7.5 | 46 |

| 12.5 | 50 | 39 | 2 | |||||

| 15 | 48 | 43 | 2.5 | |||||

| 1450 | 3.7 | 13.1 | 23 | 2 | 1.1 | |||

| 6.3 | 12.5 | 33 | 2 | |||||

| 7.5 | 12 | 36 | 2.5 | |||||

| TL50-250 | 2900 | 7.5 | 82 | 23 | 2 | 50Г—50 | 11 | 80 |

| 12.5 | 80 | 33 | 2 | |||||

| 15 | 78.5 | 36.5 | 2.5 | |||||

| 1450 | 3.75 | 20.5 | 17 | 2 | 1.5 | |||

| 6.3 | 20 | 27 | 2 | |||||

| 7.5 | 19.5 | 31 | 2.5 | |||||

| TL65-125 | 2900 | 15 | 21.8 | 17 | 2 | 65Г—65 | 3 | 38 |

| 25 | 20 | 62 | 2 | |||||

| 30 | 18.5 | 63 | 2.5 | |||||

| 1450 | 7.5 | 5.35 | 44 | 2 | 0.55 | |||

| 12.5 | 5 | 57 | 2 | |||||

| 15 | 4.7 | 59 | 2.5 | |||||

| TL65-160 | 2900 | 15 | 35 | 44 | 2 | 65Г—65 | 5.5 | 40 |

| 25 | 32 | 57 | 2 | |||||

| 30 | 30 | 59 | 2.5 | |||||

| 1450 | 7.5 | 8.8 | 39 | 2 | 1.1 | |||

| 12.5 | 8 | 51 | 2 | |||||

| 15 | 7.2 | 52.5 | 2.5 | |||||

| TL65-200 | 2900 | 15 | 53 | 41 | 2 | 65Г—65 | 11 | 49 |

| 25 | 50 | 52 | 2 | |||||

| 30 | 47 | 53.5 | 2.5 | |||||

| 1450 | 7.5 | 13.2 | 35 | 2 | 1.5 | |||

| 12.5 | 12.5 | 46 | 2 | |||||

| 15 | 11.8 | 47.5 | 2.5 | |||||

| TL65-250 | 2900 | 15 | 82 | 34 | 2 | 65Г—65 | 18.5 | 87 |

| 25 | 80 | 46 | 2 | |||||

| 30 | 78 | 50 | 2.5 | |||||

| 1450 | 7.5 | 21 | 28 | 2 | 3 | |||

| 12.5 | 20 | 39 | 2 | |||||

| 15 | 19.4 | 43 | 2.5 | |||||

| TL65-315 | 2900 | 15 | 127 | 28 | 2.5 | 65Г—65 | 30 | 119 |

| 25 | 125 | 39 | 2.5 | |||||

| 30 | 123 | 42.5 | 3 | |||||

| 1450 | 7.5 | 32.3 | 22 | 2.5 | 5.5 | |||

| 12.5 | 32 | 33 | 2.5 | |||||

| 15 | 31.7 | 37 | 3 | |||||

| TL80-125 | 2900 | 30 | 22.5 | 53 | 3 | 80Г—80 | 5.5 | 42 |

| 50 | 20 | 63 | 3 | |||||

| 60 | 18 | 52 | 3.5 | |||||

| 1450 | 15 | 5.6 | 44 | 2.5 | 1.1 | |||

| 25 | 5 | 57 | 2.5 | |||||

| 30 | 4.5 | 58 | 3 | |||||

| TL80-160 | 2900 | 30 | 36 | 57 | 2.5 | 80Г—80 | 11 | 44 |

| 50 | 32 | 67 | 2.5 | |||||

| 60 | 29 | 65 | 3 | |||||

| 1450 | 15 | 9 | 50 | 2.5 | 1.5 | |||

| 25 | 8 | 62 | 2.5 | |||||

| 30 | 7.2 | 62 | 3 | |||||

| TL80-200 | 2900 | 30 | 53 | 53 | 2.5 | 80Г—80 | 15 | 51 |

| 50 | 50 | 63 | 2.5 | |||||

| 60 | 47 | 62 | 3 | |||||

| 1450 | 15 | 13.2 | 44 | 2.5 | 2.2 | |||

| 25 | 12.5 | 57 | 2.5 | |||||

| 30 | 11.8 | 58 | 3 | |||||

| TL80-250 | 2900 | 30 | 84 | 44 | 2.5 | 80Г—80 | 30 | 81 |

| 50 | 80 | 57 | 2.5 | |||||

| 60 | 75 | 59 | 3 | |||||

| 1450 | 15 | 21 | 39 | 2.5 | 5.5 | |||

| 25 | 20 | 51 | 2.5 | |||||

| 30 | 18.8 | 52.5 | 3 | |||||

| TL80-315 | 2900 | 30 | 128 | 39 | 2.5 | 80Г—80 | 37 | 121 |

| 50 | 125 | 51 | 2.5 | |||||

| 60 | 123 | 52.5 | 3 | |||||

| 1450 | 15 | 32.5 | 35 | 2.5 | 7.5 | |||

| 25 | 32 | 46 | 2.5 | |||||

| 30 | 31.5 | 47.5 | 3 | |||||

| TL100-125 | 2900 | 60 | 24 | 64 | 4 | 100Г—100 | 11 | 43 |

| 100 | 20 | 73 | 4.5 | |||||

| 120 | 16.5 | 63 | 5 | |||||

| 1450 | 30 | 6 | 60 | 2.5 | 1.5 | |||

| 50 | 5 | 68 | 2.5 | |||||

| 60 | 4 | 63 | 3 | |||||

| TL100-160 | 2900 | 60 | 36 | 60 | 3.5 | 100Г—100 | 15 | 63 |

| 100 | 32 | 73 | 4 | |||||

| 120 | 28 | 73 | 5 | |||||

| 1450 | 30 | 9.2 | 58 | 2 | 2.2 | |||

| 50 | 8 | 69 | 2.5 | |||||

| 60 | 6.8 | 68 | 3.5 | |||||

| TL100-200 | 2900 | 60 | 54 | 63 | 3 | 100Г—100 | 30 | 77 |

| 100 | 50 | 72 | 3.6 | |||||

| 120 | 47 | 71 | 4.8 | |||||

| 1450 | 30 | 13.5 | 60 | 2 | 5.5 | |||

| 50 | 12.5 | 68 | 2 | |||||

| 60 | 11.8 | 63 | 2.5 | |||||

| TL100-250 | 2900 | 60 | 87 | 57 | 3.5 | 100Г—100 | 45 | 92 |

| 100 | 80 | 68 | 3.8 | |||||

| 120 | 74.5 | 67 | 4.8 | |||||

| 1450 | 30 | 21.3 | 50 | 2 | 7.5 | |||

| 50 | 20 | 63 | 2 | |||||

| 60 | 19 | 64 | 2.5 | |||||

| TL100-315 | 2900 | 60 | 132 | 57 | 3.5 | 100Г—100 | 75 | 165 |

| 100 | 125 | 68 | 3.8 | |||||

| 120 | 119 | 67 | 4.8 | |||||

| 1450 | 30 | 33.5 | 44 | 2 | 11 | |||

| 50 | 32 | 58 | 2 | |||||

| 60 | 30.5 | 60 | 2.5 |

1.TLдёҚй”Ҳй’ўз«ӢејҸз®ЎйҒ“зҰ»еҝғжіөжҳҜжҢүGB5656-1994зҡ„е·Ҙиүәи®ҫи®ЎеҲ¶йҖ пјҢйҮҮз”ЁCFDи®Ўз®—жөҒдҪ“еҠЁеҠӣеӯҰпјҢеҲҶжһҗи®Ўз®—еҮәжіөеҶ…еҺӢеҠӣеҲҶеёғе’ҢйҖҹеәҰеҲҶеёғе…ізі»гҖҒдјҳеҢ–жіөзҡ„жөҒйҒ“и®ҫи®ЎпјҢзЎ®дҝқжіөжңүй«ҳж•Ҳзҡ„ж°ҙеҠӣеҪўзә?жҸҗй«ҳдәҶжіөзҡ„ж•ҲзҺҮгҖҒьbr /> 2. жіөзҡ„иҝҮжөҒйғЁд»¶еҰӮжіөдҪ“гҖҒеҸ¶иҪ®гҖҒжіөзӣ–гҖҒеҜҶе°ҒзҺҜзӯүпјҢйҮҮз”ЁзЎ…иһҚиғ¶зІҫеҜҶй“ёйҖ пјҢжөҒйҒ“е°әеҜёзЁіе®ҡпјҢ铸件жҲҗеһӢеҗҺйҮҮз”Ёй…ёжҙ—е·ҘиүәеҺ»еӨ„铸件表йқўж®Ӣз•ҷзҡ„йҷ„зқҖзү©пјҢдҝқз•ҷйҮ‘еұһжң¬иҙЁпјҢдёҚдјҡеӣ й“ёйҖ йҷ„зқҖзү©иҖҢеҪұе“Қиҫ“йҖҒзҡ„д»ӢиҙЁгҖҒьbr /> 3.йҮҮз”Ёжҷ®йҖҡеһӢе’ҢзЎ¬иҙЁеҗҲйҮ‘иҖҗи…җиҖҗзЈЁеһӢдјҳиҙЁжңәжў°еҜҶе°ҒпјҢеҮәеҺӮж—¶дҪңдёҘж јзҡ„еҜҶе°ҒиҜ•йӘ?дҝқиҜҒдәҶеҜҶе°Ғзҡ„еҸҜйқ жҖ§гҖҒьbr /> 4.иҪҙиҒ”еҗҺжӢүејҸи®ҫи®ЎпјҢиҝӣеҮәеҸЈеҸЈеҫ„зӣёеҗҢдё”еңЁдёҖжқЎзӣҙзәҝдёҠпјҢж— йңҖжӢҶеҚёз®ЎйҒ“пјҢз»ҙдҝ®ж–№дҫҝпјӣ

5.ж— йңҖзӢ¬з«Ӣж¶Ұж»‘е’ҢеҶ·еҚҙж°ҙпјҢйҷҚдҪҺдәҶиғҪиҖ—гҖҒьbr /> 6.з«ӢејҸе®үиЈ…пјҢз»“жһ„зҙ§еҮ‘гҖҒеҚ ең°йқўз§Ҝе°ҸпјҢжҢҜеҠЁе°ҸпјҢеҷӘйҹідҪҺпјҢиҝҗиЎҢе№ізЁІьbr /> 7.йҮҮз”Ёе…Ҳиҝӣзҡ„еҸҢиҠӮжөҒзҺҜе№іиЎЎжі•пјҢиҪҙеҗ‘еҠӣе№іиЎЎж•ҲжһңеҘҪпјҢжңүж•ҲеҮҸе°‘з”өжңәж•…йҡңзҺҮпјҢжҸҗй«ҳиҝҗиЎҢеҸҜйқ жҖ§пјӣе№іиЎЎзІҫеәҰй«ҳпјҢеҸ¶иҪ®йғЁд»¶еҠЁе№іиЎЎзІҫеәҰдёәG1.0зә§гҖ

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„е·ҘдҪңеҺҹзҗҶд»Ӣз»Қпјһь/li>

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„е·ҘдҪңеҺҹзҗҶд»Ӣз»Қпјһь/li> з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„дҪҝз”Ёж–№жі•пјһь/li>

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„дҪҝз”Ёж–№жі•пјһь/li> з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөеӨҡе°‘й’ұдёҖеҸ°пјҹ

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөеӨҡе°‘й’ұдёҖеҸ°пјҹ з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөдҪҝз”Ёзҡ„жіЁж„ҸдәӢйЎ№

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөдҪҝз”Ёзҡ„жіЁж„ҸдәӢйЎ№ з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„иҜҙжҳҺд№Ұжңүеҗ—пјҹ

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„иҜҙжҳҺд№Ұжңүеҗ—пјҹ з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„ж“ҚдҪң规зЁӢжңүеҗ—пјһь/li>

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„ж“ҚдҪң规зЁӢжңүеҗ—пјһь/li> з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„жҠҘд»·еҗ«зҘЁеҗ«иҝҗиҙ№еҗ—пјһь/li>

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөзҡ„жҠҘд»·еҗ«зҘЁеҗ«иҝҗиҙ№еҗ—пјһь/li> з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөжңүзҺ°иҙ§еҗ—пјҹ

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөжңүзҺ°иҙ§еҗ—пјҹ з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөеҢ…е®үиЈ…еҗ—пјҹ

з«ӢејҸз®ЎйҒ“зҰ»еҝғжіөеҢ…е®үиЈ…еҗ—пјҹ жүӢжңәзүҲпјҡ

жүӢжңәзүҲпјҡ

cnpowder е№іеҸ°еҜјиҲӘ|дёӯеӣҪзІүдҪ“зҪҗь/a>жҗңзІүзҪҗь/a>зІүдҪ“еұ”ь/a>зІүдҪ“дәәжүҚзҪҗь/a>зІүдҪ“е·ҘдёҡжқӮеҝ—еҫ®й—ЁжҲ¶ь/a>жүӢжңәзІүдҪ“зҪҗь/a>зІүдҪ“еңҲеӯҗзІүдҪ“е…¬ејҖиҜҪь/a>зІүдә«д№°еҚ–дёӯзІүиө„и®Ҝ

йҡҗз§ҒдҝқжҠӨ дёӯеӣҪзІүдҪ“зҪ зүҲжқғжүҖжң дә¬ICPиҜ?50428еҸ е®ўжҲ·жңҚеҠЎзғӯзәҝпј?10-82930764 82930964

е®ўжңҚйӮ®з®ұпјҡcnpowder@163.com дә¬е…¬зҪ‘е®үеӨ?101081901еҸ

CopyrightВ©2002-2024 Cnpowder.com.cn Corporation,All Rights Reserved