зҷ»еҪ•

- APP

- зІүдә«йҖҷь/a>

- 188188188b.comҪрұҰІ©

еҫ®дҝЎ

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

- дёӯеӣҪзІүдҪ“зҪҗь/a>

移еҠЁз«?/p>

移еҠЁз«?/p>

m.cnpowder.com.cn

m.cnpowder.com.cn

зҷ»еҪ•

еҫ®дҝЎ

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

![]() 移еҠЁз«?/p>

移еҠЁз«?/p>

m.cnpowder.com.cn

m.cnpowder.com.cn

еҸӮиҖғд»·ж »ь/p>йқўи®®

еһӢеҸ·

е“ҒзүҢ

дә§ең°

зҫҺеӣҪж ·жң¬

жҡӮж— з•ҷиЁҖиҜўд»·

з•ҷиЁҖиҜўд»·

иҷҡжӢҹеҸ·е°Ҷең180з§’еҗҺеӨұж•Ҳ

дҪҝз”Ёеҫ®дҝЎжү«з ҒжӢЁеҸ·

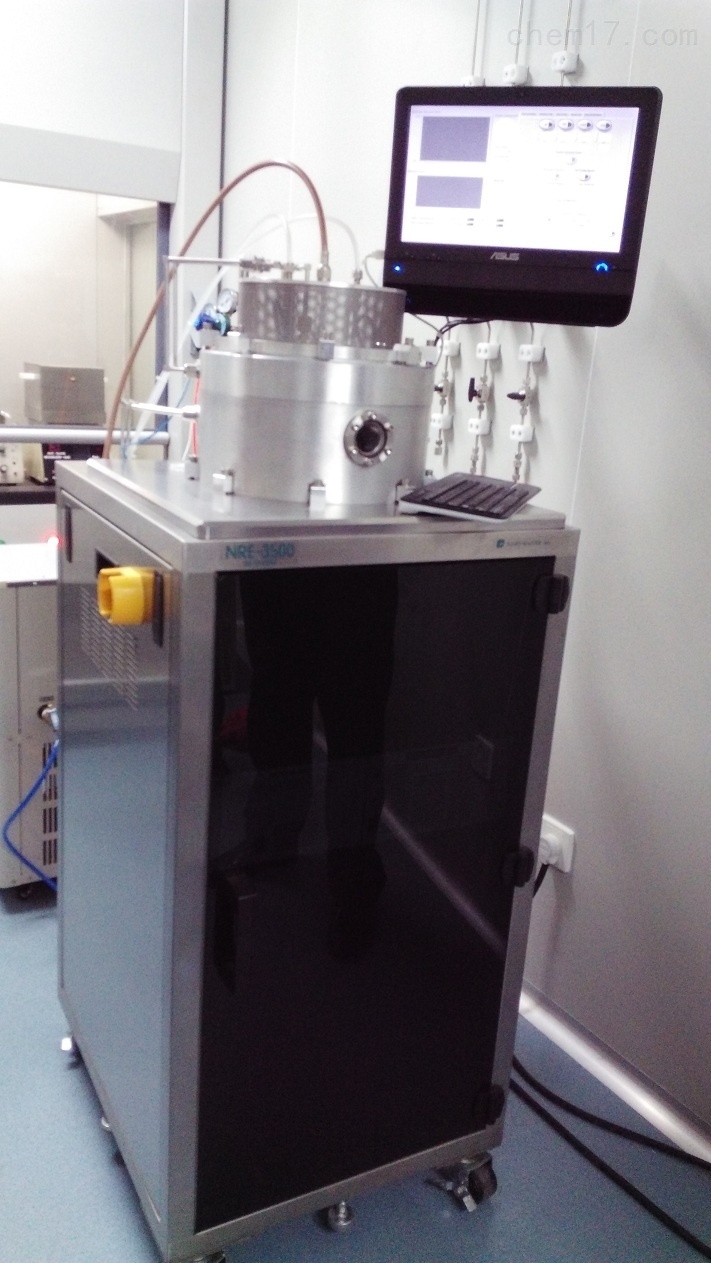

IBEзҰ»еӯҗжқҹеҲ»иҡҖзі»з»ҹ

NIE-4000пјҲAпјүе…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖдә§е“ҒжҰӮиҝ°пјҷьspan>еҰӮй“ңе’ҢйҮ‘зӯүйҮ‘еұһдёҚеҗ«жҢҘеҸ‘жҖ§еҢ–еҗҲзү©пјҢиҝҷдәӣйҮ‘еұһзҡ„еҲ»иҡҖж— жі•ең?/span>RIEзі»з»ҹдёӯе®ҢжҲҗгҖӮ然иҖҢйҖҡиҝҮеҠ йҖҹзҡ„ArзҰ»еӯҗиҝӣиЎҢзү©зҗҶеҲ»иҡҖеҲҷжҳҜеҸҜиғҪзҡ„гҖӮйҖҡеёёжғ…еҶөдёӢпјҢж ·е“ҒиЎЁйқўйҮҮз”ЁеҺҡиғ¶дҪңдёәжҺ©жЁЎеұӮпјҢеҲ»иҡҖжңҹй—ҙеҜҢжңүиғҪйҮҸзҡ„зҰ»еӯҗжөҒдјҡдҪҝеҫ—еҹәзүҮе’Ңе…үеҲ»иғ¶иҝҮзғӯгҖӮйҷӨйқһеҸҜд»ҘжүҫеҲ°жңүж•Ҳзҡ„ж–№ејҸж¶ҲйҷӨзғӯйҮҸпјҢеҗҰеҲҷе…үеҲ»иғ¶е°ҶеҸҳеҫ—йқһеёёйҡҫд»ҘеҺ»йҷӨгҖҒь/span>

NANO-MASTERжҠҖжңҜе·Із»ҸиҜҒжҳҺдәҶеҸҜд»ҘжҠҠеҹәзүҮжё©еәҰжҺ§еҲ¶еңЁ50Ўг Cд»ҘеҶ…зҡ„еҗҢж—¶пјҢж—ӢиҪ¬жҷ¶еңҶзүҮд»ҘиҫҫеҲ°жғіиҰҒзҡ„еқҮеҢҖеәҰгҖҒь/span>

NIE-4000пјҲAпјүе…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖдә§е“Ғзү№зӮ№пјҷь/p>

14.5вҖңь/span>дёҚй”Ҳй’ўз«ӢдҪ“зҰ»еӯҗжқҹи…”дҪ“

16cm DCзҰ»еӯҗжһ?/span>1200eVпј?50mAпјж°”еҠЁдёҚй”Ҳй’ўйҒ®жқҫь/span>

зҰ»еӯҗжқҹдёӯе’ҢеҷЁ

ж°©ж°”MFC

6вҖңь/span>ж°ҙеҶ·ж ·е“ҒеҸ?/span>

жҷ¶зүҮж—ӢиҪ¬йҖҹеәҰ3гҖ?/span>10RPMпјҢзңҹз©әжӯҘиҝӣз”өжң№ь/span>

жӯҘиҝӣз”өжңәжҺ§еҲ¶жҷ¶еңҶзүҮеҖҫж–ң

иҮӘеҠЁдёҠдёӢиҪҪжҷ¶еңҶзүҮ

е…ёеһӢеҲ»иҡҖйҖҹзҺҮпјҡй“ң200 ?/minпјзЎ…пјҡ500 ?/min

6вҖңь/span>иҢғеӣҙеҶ…пјҢеҲ»иҡҖеқҮеҢҖеә?/span>+/-3%

жһҒйҷҗзңҹз©ә5x10-7TorrпјӢь/span>20еҲҶй’ҹеҶ…еҸҜиҫҫеҲ°10-6Torrзә§еҲ«пјҲй…ҚеҘ–ь/span>500 l/sж¶ЎиҪ®еҲҶеӯҗжіөпјү

й…ҚеҘ—1000 l/sж¶ЎиҪ®еҲҶеӯҗжіөпјҢжһҒйҷҗзңҹз©әеҸҜиҫҫ8x10-8Torr

зЈҒжҺ§жә…е°„Si3N4д»ҘдҝқжҠӨиў«еҲ»иҡҖйҮ‘еұһиЎЁйқўиў«ж°§еҢ•ь/span>

еҹәдәҺLabViewиҪҜ件зҡғь/span>PCи®Ўз®—жңәе…ЁиҮӘеҠЁжҺ§еҲ¶

иҸңеҚ•й©ұеҠЁпјӢь/span>4зә§еҜҶз Ғи®ҝй—®дҝқжҠЈь/span>

е®Ңж•ҙзҡ„е®үе…ЁиҒ”й”?/span>

NIE-4000пјҲAпјүе…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖFeaturesпјҷь/p>

14.5" SS Cube ion beam chamber

16 cm DC Ion gun 1000Vпј 500 mA пјҢDC motor driven SS shutters

Ion Beam neutralizer

Ar MFC

Chilled water cooled 6вҖ substrate platen

Wafer rotation 3-10 RPMпј Vacuum stepper motor

Wafer Tilt with a stepper motor through differentially pumped rotational seal

Manual wafer load/unload

Typical Etch Rates: 200 ?/min Cuпј 500 ?/min Si

+/-3% etch uniformity over 6вҖ area

5x 10-6Torr < 20 minutes <2 x10-7Torr (2 days) Base Pressure with 500 l/sec turbo

8x10-8Torr Base pressure with 1000 l/sec Turbo pump

Magnetron Sputtering of Si3N4to protect etched metal surfaces from oxidation

PC Controlled with LabVIEW Software

Recipe Drivenпј Password Protected

Fully Safety Interlocked

жҡӮж— ж•°жҚ®пј

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„е·ҘдҪңеҺҹзҗҶд»Ӣз»Қпјҹ

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„е·ҘдҪңеҺҹзҗҶд»Ӣз»Қпјҹ NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„дҪҝз”Ёж–№жі•пјҹ

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„дҪҝз”Ёж–№жі•пјҹ NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖеӨҡе°‘й’ұдёҖеҸ°пјҹ

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖеӨҡе°‘й’ұдёҖеҸ°пјҹ NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖдҪҝз”Ёзҡ„жіЁж„ҸдәӢйЎёь/li>

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖдҪҝз”Ёзҡ„жіЁж„ҸдәӢйЎёь/li> NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„иҜҙжҳҺд№Ұжңүеҗ—пјһь/li>

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„иҜҙжҳҺд№Ұжңүеҗ—пјһь/li> NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„ж“ҚдҪң规зЁӢжңүеҗ—пјҹ

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„ж“ҚдҪң规зЁӢжңүеҗ—пјҹ NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„жҠҘд»·еҗ«зҘЁеҗ«иҝҗиҙ№еҗ—пјҹ

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖзҡ„жҠҘд»·еҗ«зҘЁеҗ«иҝҗиҙ№еҗ—пјҹ NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖжңүзҺ°иҙ§еҗ—пјһь/li>

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖжңүзҺ°иҙ§еҗ—пјһь/li> NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖеҢ…е®үиЈ…еҗ—пјһь/li>

NIE-4000 (A)е…ЁиҮӘеҠЁIBEзҰ»еӯҗжқҹеҲ»иҡҖеҢ…е®үиЈ…еҗ—пјһь/li> жүӢжңәзүҲпјҡ

жүӢжңәзүҲпјҡ

cnpowder е№іеҸ°еҜјиҲӘ|дёӯеӣҪзІүдҪ“зҪҗь/a>жҗңзІүзҪҗь/a>зІүдҪ“еұ”ь/a>зІүдҪ“дәәжүҚзҪҗь/a>зІүдҪ“е·ҘдёҡжқӮеҝ—еҫ®й—ЁжҲ¶ь/a>жүӢжңәзІүдҪ“зҪҗь/a>зІүдҪ“еңҲеӯҗзІүдҪ“е…¬ејҖиҜҪь/a>зІүдә«д№°еҚ–дёӯзІүиө„и®Ҝ

йҡҗз§ҒдҝқжҠӨ дёӯеӣҪзІүдҪ“зҪ зүҲжқғжүҖжң дә¬ICPиҜ?50428еҸ е®ўжҲ·жңҚеҠЎзғӯзәҝпј?10-82930764 82930964

е®ўжңҚйӮ®з®ұпјҡcnpowder@163.com дә¬е…¬зҪ‘е®үеӨ?101081901еҸ

CopyrightВ©2002-2024 Cnpowder.com.cn Corporation,All Rights Reserved