зҷ»еҪ•

- APP

- зІүдә«йҖҷь/a>

- 188188188b.comҪрұҰІ©

еҫ®дҝЎ

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

- дёӯеӣҪзІүдҪ“зҪҗь/a>

移еҠЁз«?/p>

移еҠЁз«?/p>

m.cnpowder.com.cn

m.cnpowder.com.cn

зҷ»еҪ•

еҫ®дҝЎ

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

е…іжіЁеҫ®дҝЎе…¬дј—еҸ¶ь/span>

![]() 移еҠЁз«?/p>

移еҠЁз«?/p>

m.cnpowder.com.cn

m.cnpowder.com.cn

еҸӮиҖғд»·ж »ь/p>йқўи®®

еһӢеҸ·

й«ҳжё©зҹіеўЁзӮүGRF-2000Cе“ҒзүҢ

иҙқж„Ҹе…Ҡь/span>дә§ең°

е®үеҫҪеҗҲиӮҘж ·жң¬

жҡӮж—йҮ‘еұһз”өзғӯе…ғ件пјҷь/p>е…¶д»–

зғ§з»“ж°”ж°ӣпјҷь/p>е…¶д»–

жё©жҺ§зІҫеәҰпјҷь/p>+1

жңҖй«ҳжё©еәҰпјҡ

2000йўқе®ҡжё©еәҰпјҷь/p>2000

йқһйҮ‘еұһз”өзғӯе…ғ件пјҡ

е…¶д»– з•ҷиЁҖиҜўд»·

з•ҷиЁҖиҜўд»·

з”өиҜқиҜўд»·

з”өиҜқиҜўд»·

иҷҡжӢҹеҸ·е°Ҷең180з§’еҗҺеӨұж•Ҳ

дҪҝз”Ёеҫ®дҝЎжү«з ҒжӢЁеҸ·

дё»иҰҒзү№зӮ№Main features:

This equipment is periodic operation type.

жң¬и®ҫеӨҮдёәе‘ЁжңҹдҪңдёҡејҺь/p>

Widely used in functional ceramics, optical materials, carbon composites, cemented carbides, powder metallurgy and so on to be sintered at high temperature, and can also be formed and sintered under the condition of aeration protection.

е№ҝжіӣеә”з”ЁдәҺеҠҹиғҪйҷ¶з“·гҖҒе…үеӯҰжқҗж–ҷгҖҒзўіеӨҚеҗҲжқҗж–ҷпјҢзЎ¬иҙЁеҗҲйҮ‘пјҢзІүжң«еҶ¶йҮ‘зӯүеңЁй«ҳжё©дёӢиҝӣиЎҢзғ§з»“еӨ„зҗҶпјҢд№ҹеҸҜеңЁе……ж°”дҝқжҠӨжғ…еҶөдёӢжҲҗеһӢзғ§з»“гҖҒь/p>

жҠҖжңҜеҸӮж•°Structure specificationпјҷь/strong>

Furnace body зӮүдҪ“ |

Double layer water sandwich structure.The inner wall is stainless steel polished and the outer wall is high quality carbon steel йҮҮз”ЁеҸҢеұӮж°ҙеӨ№еұӮз»“жһ„пјҢеҶ…еЈҒдёәдёҚй”Ҳй’ўжҠӣе…үпјҢеӨ–еЈҒдёәдјҳиҙЁзўій’ўгҖҒь/p> The upper and lower flanges are welded into a cylindrical structure, and the flange plane is provided with a seal groove. дёҠгҖҒдёӢжі•е…°з»„з„ҠжҲҗзӯ’еһӢз»“жһ„пјҢжі•е…°е№ійқўејҖи®ҫеҜҶе°Ғж§ҪгҖҒь/p> Adopt ring vacuum seal, and set up water cooling device (prevent aging due to excessive temperature ring) йҮҮз”Ёиғ¶еңҲзңҹз©әеҜҶе°ҒпјҢ并и®ҫж°ҙеҶ·иЈ…зҪ®пјҲйҳІжӯўеӣ жё©еәҰиҝҮй«ҳиғ¶еңҲиҖҒеҢ–пјүгҖҒь/p> Equipped with observation window and shield, air extraction hole, temperature measurement using tungsten-rhenium thermocouple зӮүдҪ“и®ҫзҪ®и§ӮеҜҹзӘ—еҸҠеұҸи”ҪгҖҒжҠҪж°”еӯ”гҖҒжөӢжё©йҮҮз”Ёй’Ёй“јзғӯз”өеҒ¶гҖҒь/p> |

Furnace cover зӮүзӣ– |

Double layer water sandwich structure,equipped with observation holes, shielding and locking devices, opening devices, and water cooling devices. йҮҮз”ЁеҸҢеұӮеӨ№еұӮе°ҒеӨҙз»“жһ„пјҢи®ҫзҪ®и§ӮеҜҹеӯ”гҖҒеұҸи”ҪеҸҠй”Ғзҙ§иЈ…зҪ®еҸҠеҗҜејҖиЈ…зҪ®гҖҒ并и®ҫж°ҙеҶ·иЈ…зҪ®гҖҒь/p> |

Furnace bottom зӮүеә• |

Double layer water sandwich structure, water cooling devices йҮҮз”ЁеҸҢеұӮж°ҙеӨ№еұӮе°ҒеӨҙз»“жһ„пјҢ并и®ҫж°ҙеҶ·иЈ…зҪ®гҖҒь/p> |

Furnace frame зӮүжһ¶ |

The furnace body is placed on the box body with welded box structure of section steel and steel plate. з”ұеһӢй’ўеҸҠй’ўжқҝз»„з„ҠжҲҗз®ұејҸз»“жһ„пјҢзӮүдҪ“е®үж”ҫеңЁз®ұдҪ“дёҠгҖҒь/p> |

Vacuum unit зңҹз©әзі»з»ҹ |

Connected by a direct pump, a diffuser pump, a manual butterfly valve, a vacuum pressure gauge, an inflatable valve, an air relief valve, a vacuum pipe and a pump з”ұдёҖеҸ°зӣҙиҒ”жіөгҖҒдёҖеҸ°жү©ж•ЈжіөгҖҒжүӢеҠЁиқ¶йҳҖгҖҒзңҹз©әеҺӢеҠӣиЎЁгҖҒе……ж°”йҳҖгҖҒж”ҫж°”йҳҖгҖҒзңҹз©әз®ЎйҒ“дёҺжіөзҡ„иҒ”жҺҘ Quick joint connection with metal corrugated hoseпјҲSlow down the vibrationпјҲь/p> йҮҮз”ЁйҮ‘еұһжіўзә№иҪҜз®Ўеҝ«йҖҹжҺҘеӨҙиҒ”жҺҘпјҲеҮҸзј“йңҮеҠЁпјүпјҢ Vacuum measured by a digital display composite vacuum gauge зңҹз©әеәҰзҡ„жөӢйҮҸз”ұж•°жҳҫеӨҚеҗҲзңҹз©әи®Ўжү§иЎҢгҖҒь/p> |

Electric control з”өж°”жҺ§еҲ¶ |

Silicon controlled temperature control, with a large current transformer, voltage regulator and temperature control instrument composed of temperature control execution circuit. йҮҮз”ЁеҸҜжҺ§зЎ…жҺ§жё©пјҢй…ҚжңүеӨ§з”өжөҒеҸҳеҺӢеҷЁгҖҒи°ғеҺӢеҷЁеҸҠжё©еәҰжҺ§еҲ¶д»ӘиЎЁз»„жҲҗжё©еәҰжҺ§еҲ¶жү§иЎҢеӣһи·ҜгҖҒь/p> The circuit has the functions of water cut, overcurrent, overtemperature alarm and protection. з”өи·Ҝи®ҫзҪ®ж–ӯж°ҙгҖҒиҝҮжөҒгҖҒи¶…жё©жҠҘиӯҰеҸҠдҝқжҠӨеҠҹиғҪгҖҒь/p> |

Temperature control жҺ§жё©зі»з»ҹ |

Using controllable silicon and digital display temperature controlпјҲHoneywell, USAпјҲь/p> йҮҮз”ЁеҸҜжҺ§еҲ¶зЎ…жҺ§жё©пјҢд»ӘиЎЁдёәзҫҺеӣҪйңҚе°јйҹҰе°”ж•°жҳҫиЎЁжҺ§жё?/p> P.I.D regulation, Super temperature sound and light alarm function е…·жңүP.I.Dи°ғиҠӮгҖҒи¶…жё©еЈ°е…үжҠҘиӯҰеҠҹиғҪпјҢ |

Water cooling ж°ҙеҶ·зі»з»ҹ |

Consists of various pipe valves and other related devices. It has the function of water pressure underpressure, acousto-optic alarm of water cut off power supply automatically. з”ұеҗ„з§Қз®ЎйҒ“йҳҖзӯүзӣёе…іиЈ…зҪ®з»„жҲҗпјҢе…·жңүж°ҙеҺӢж¬ еҺӢгҖҒж–ӯж°ҙеЈ°е…үжҠҘиӯҰиҮӘеҠЁеҲҮж–ӯз”өжәҗеҠҹиғҪгҖҒь/p> |

Gas system ж°”и·Ҝзі»з»ҹ |

The system is equipped with an air inlet and an outlet, which can be filled with atmosphere. ж•ҙдёӘзі»з»ҹдёӯи®ҫзҪ?дёӘиҝӣж°”еҸЈгҖ?дёӘж”ҫж°”еҸЈпјҢеҸҜе……ж°”ж°ӣгҖҒь/p> |

Heating element, heat shield еҸ‘зғӯе…ғ件гҖҒйҡ”зғӯеұҸ |

The heating body is fabricated into a cylindrical structure with domestic graphite electrode еҸ‘зғӯдҪ“йҮҮз”ЁеӣҪдә§з”өжһҒзҹіеўЁеҠ е·ҘжҲҗеңҶзӯ’еҪўз»“жһ„гҖҒь/p> The heat insulation screen adopts the composite structure of graphite cylinder and carbon felt. It has good thermal insulation property, uniform heating, large radiation surface, good heat resistance and impact resistance, and can be heated quickly. йҡ”зғӯеұҸйҮҮз”ЁзҹіеўЁзӯ’еҸҠзўіжҜЎзҡ„еӨҚеҗҲз»“жһ„пјҢдҝқжё©жҖ§иғҪеҘҪпјҢеҠ зғӯеқҮеҢҖпјҢиҫҗе°„йқўеӨ§пјҢиҖҗзғӯеҶІеҮ»жҖ§еҘҪпјҢеҸҜеҝ«йҖҹеҠ зғӯгҖҒь/p> Insulation layer and heater, easy to maintain and dismount, insulation jacket external stainless steel frame structure fixed. дҝқжё©еұӮе’ҢеҸ‘зғӯдҪ“пјҢжҳ“з»ҙжҠӨе’ҢеҸ–иЈ…пјҢдҝқжё©еҘ—еӨ–з”ЁдёҚй”Ҳй’ўжЎҶжһ¶з»“жһ„еӣәе®ҡгҖҒь/p> |

Transformers and connecting copper bars еҸҳеҺӢеҷЁеҸҠиҒ”жҺҘй“ңжҺ’ |

Use of transformers and copper bars matched with power йҮҮз”ЁдёҺдҪҝз”ЁеҠҹзҺҮзӣёеҢ№й…Қзҡ„еҸҳеҺӢеҷЁеҸҠй“ңжҺ’гҖҒь/p> |

Gas charging and discharging system е……ж”ҫж°”зі»з»һь/p> |

The utility model consists of a variety of pipes and manual vacuum diaphragm valves, which facilitate the user to connect the gas path. з”ұеҗ„з§Қз®ЎйҒ“еҸҠжүӢеҠЁзңҹз©әйҡ”иҶңйҳҖз»„жҲҗпјҢж–№дҫҝз”ЁжҲ·иҝһжҺҘж°”и·ҜгҖҒь/p> |

жҠҖжңҜеҸӮж•°Technical Parametersпјҷь/strong>

Power иҫ“е…Ҙз”өжәҗ |

Power rated:20KW йўқе®ҡеҠҹзҺҮпј?0KW |

Voltage з”өеҺӢ |

Voltage rated: AC380V 508HZ йўқе®ҡз”өеҺӢпјҡAC380V 50HZ |

Working Temperature е·ҘдҪңжё©еәҰ |

Max. Temperature: 2000в„Ӯь/span> **жё©еәҰпј?000в„Ӯь/p> Continuous working temperature: вү?900в„Ӯь/p> жҢҒз»ӯе·ҘдҪңжё©еәҰпјҡвүӨ1900в„Ӯь/p> |

Temperature Controller жҺ§жё©ж–№ејҸ |

Digital display temperature programmed thermometer ж•°жҳҫжё©еәҰзЁӢеәҸжҺ§жё©д»?/p> Thyristor voltage regulator or Automatic chain protection control еҸҜжҺ§зЎ…з”өеҺӢи°ғж•ҙеҷЁжҲ–иҮӘеҠЁиҝһй”ҒдҝқжҠӨжҺ§еҲөь/p> |

Heating Elements еҠ зғӯе…ғ件 |

Graphite heater зҹіеўЁеҸ‘зғӯдҪ’ь/p> |

Temperature measurment жөӢжё©ж–№ејҸ |

Tungsten rhenium thermocouple й’Ёй“јзғӯз”өеҒөь/p> |

Temperature Accuracy жҺ§жё©зІҫеәҰ |

+/- 1в„Ӯь/span> |

Chamber size зӮүиҶӣе°әеҜё |

ОҰ100*200mm |

Pressure rise rate еҺӢеҚҮзҺҶь/p> |

2PaвҲ•h |

Charged pressure е……ж°”еҺӢеҠӣ |

0.1 Mpa(inflatable for Nitrogen,Argon,and mixed gas пјҲеҸҜе……ж°®ж°”гҖҒж°©ж°”еҸҠж··еҗҲж°”дҪ“пјҲь/p> |

Ultimate vacuum under cold state еҶ·жҖҒжһҒйҷҗзңҹз©№ь/p> |

6.67*10 -3pa |

Warranty иҙЁдҝқ |

One year limited warranty with lifetime support (Such consumable parts as silicon ring are NOT supported by the warranty) дёҖе№ҙиҙЁдҝқз»Ҳиә«ж”ҜжҢҒпјҲж¶ҲиҖ—е“ҒеҰӮзЎ…иғ¶еңҲдёҚеңЁиҙЁдҝқиҢғеӣҙеҶ…пјү |

Compliance и®ӨиҜҒ |

CE Certified CEи®ӨиҜҒ The furnace is ready to pass TUV (UL61010) or CSA certification at extra cost. еҸҜд»ҳиҙ№иҝӣиЎҢTUV(UL61010)жҲ–CSAи®ӨиҜҒ |

жҡӮж— ж•°жҚ®пј

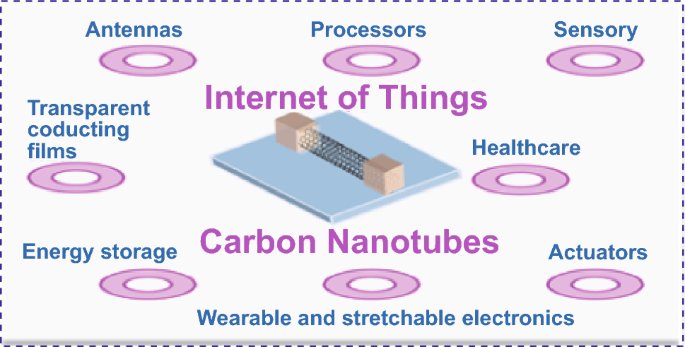

еҗҺж‘©е°”е®ҡеҫӢж—¶д»ЈжҺЁеҠЁдәҶзўіеҹәз”өеӯҗжҷ¶дҪ“з®Ўзҡ„еҝ«йҖҹеҸ‘еұ•гҖ?GйҖҡдҝЎе’Ңдә‘и®Ўз®—дҝғиҝӣдәҶеҹәдәҺзўізәізұіз®Ўзҡ„еңәж•Ҳеә”жҷ¶дҪ“з®ЎеңЁз”өеӯҗи®ҫеӨҮдёӯзҡ„еә”з”ЁгҖӮжң¬ж–Үе°ҶйҮҚзӮ№е…іжіЁзўіеҹәз”өеӯҗйўҶеҹҹзҡ„жңҖж–°з ”з©¶зғӯзӮ№пјҢеҢ…жӢ¬й«ҳйў‘жҷ¶дҪ“з®ЎгҖҒз”ҹзү©еҢ»еӯҰдј ж„ҹеҷЁе’ҢеҲ¶еҠЁеҷЁгҖҒи„‘жң№ь/p>

й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„е·ҘдҪңеҺҹзҗҶд»Ӣз»Қпјҹ

й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„е·ҘдҪңеҺҹзҗҶд»Ӣз»Қпјҹ й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„дҪҝз”Ёж–№жі•пјҹ

й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„дҪҝз”Ёж–№жі•пјҹ й«ҳжё©зҹіеўЁзӮүGRF-2000CеӨҡе°‘й’ұдёҖеҸ°пјҹ

й«ҳжё©зҹіеўЁзӮүGRF-2000CеӨҡе°‘й’ұдёҖеҸ°пјҹ й«ҳжё©зҹіеўЁзӮүGRF-2000CдҪҝз”Ёзҡ„жіЁж„ҸдәӢйЎёь/li>

й«ҳжё©зҹіеўЁзӮүGRF-2000CдҪҝз”Ёзҡ„жіЁж„ҸдәӢйЎёь/li> й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„иҜҙжҳҺд№Ұжңүеҗ—пјһь/li>

й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„иҜҙжҳҺд№Ұжңүеҗ—пјһь/li> й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„ж“ҚдҪң规зЁӢжңүеҗ—пјҹ

й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„ж“ҚдҪң规зЁӢжңүеҗ—пјҹ й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„жҠҘд»·еҗ«зҘЁеҗ«иҝҗиҙ№еҗ—пјҹ

й«ҳжё©зҹіеўЁзӮүGRF-2000Cзҡ„жҠҘд»·еҗ«зҘЁеҗ«иҝҗиҙ№еҗ—пјҹ й«ҳжё©зҹіеўЁзӮүGRF-2000CжңүзҺ°иҙ§еҗ—пјһь/li>

й«ҳжё©зҹіеўЁзӮүGRF-2000CжңүзҺ°иҙ§еҗ—пјһь/li> й«ҳжё©зҹіеўЁзӮүGRF-2000CеҢ…е®үиЈ…еҗ—пјһь/li>

й«ҳжё©зҹіеўЁзӮүGRF-2000CеҢ…е®үиЈ…еҗ—пјһь/li> жүӢжңәзүҲпјҡ

жүӢжңәзүҲпјҡ

cnpowder е№іеҸ°еҜјиҲӘ|дёӯеӣҪзІүдҪ“зҪҗь/a>жҗңзІүзҪҗь/a>зІүдҪ“еұ”ь/a>зІүдҪ“дәәжүҚзҪҗь/a>зІүдҪ“е·ҘдёҡжқӮеҝ—еҫ®й—ЁжҲ¶ь/a>жүӢжңәзІүдҪ“зҪҗь/a>зІүдҪ“еңҲеӯҗзІүдҪ“е…¬ејҖиҜҪь/a>зІүдә«д№°еҚ–дёӯзІүиө„и®Ҝ

йҡҗз§ҒдҝқжҠӨ дёӯеӣҪзІүдҪ“зҪ зүҲжқғжүҖжң дә¬ICPиҜ?50428еҸ е®ўжҲ·жңҚеҠЎзғӯзәҝпј?10-82930764 82930964

е®ўжңҚйӮ®з®ұпјҡcnpowder@163.com дә¬е…¬зҪ‘е®үеӨ?101081901еҸ

CopyrightВ©2002-2024 Cnpowder.com.cn Corporation,All Rights Reserved